Ceramics

Today's market places the highest demands on product quality and traceability. With our newly developed, fully automatic inspection machine, we are setting a new standard in quality control in the ceramics industry. It reliably detects surface defects, microcracks, inclusions, dimensional deviations and coating irregularities – more precisely and efficiently than conventional systems. The system is already in successful use at our first customer and impresses with its outstanding performance and satisfaction.

CTI

Ceramic Tableware Inspection

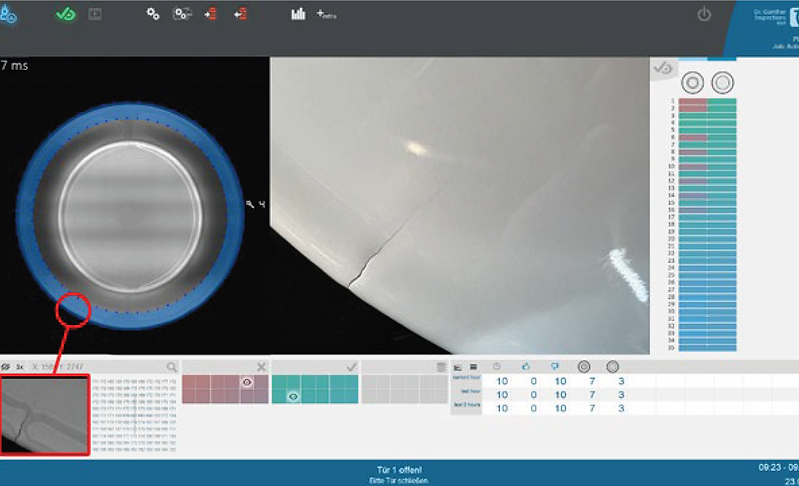

Check for defects

- contaminations, cracks, misprints or missing glaze

Measurement of dimensions

- length, width, diameter and ovality

Double-sided inspection

without rotating the article

Crack detection

Identification of cracks of all kinds

Contamination

Detection of all kinds of contaminations from above an below

Deformation / Firing marks / Logo inspection

- Detection of deformations and dimensional deviations

- Detection of firing marks before and after polishing

- Logo inspection by cover ratio or by AI

Multiple inspection zones

No article rotation necessary

Multiple freely definable inspection zones can be configured on a plate or bowl from above and below. Each zone can be individually adjusted in position and quality standard.

Simple user interface